Plastic Bulk Containers for Reducing Operational Costs Efficiently

A Comprehensive Guide to Selecting the Right Bulk Containers for Optimal Storage Space and Transportation

Choosing the ideal mass containers is a vital choice for companies involved in storage and transport. Various elements affect this option, including material compatibility and dimension demands. Different industries have distinct demands that must be satisfied to ensure security and effectiveness. Recognizing these aspects can greatly impact logistics and product integrity. The following sections will check out crucial factors to consider and ideal techniques thoroughly, disclosing what truly matters in container option.

Understanding Various Sorts Of Bulk Containers

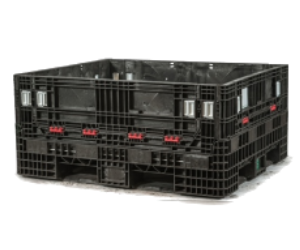

Mass containers work as essential tools in the storage and transport of different products, varying from liquids to solids. These containers come in varied kinds, each developed for certain applications. Usual kinds include Intermediate Mass Containers (IBCs), which are excellent for transferring liquids, granules, or powders. Totes, an additional version, are ideal for both solids and fluids and can be stacked for reliable storage space. In addition, bulk bags, often made from woven fabric, are utilized to handle completely dry mass materials. For solid products, bulk bins give tough, stackable options that maximize space. Each kind of bulk container offers an unique function, assisting in reliable motion and storage space, while making certain safety and security and conformity with industry criteria. Understanding these choices is vital for efficient logistics monitoring.

Benefits and Downsides of Typical Bulk Container Options

When evaluating mass container options, it is crucial to contemplate both their drawbacks and benefits. As an example, inflexible containers, such as steel or plastic containers, use resilience and defense versus ecological aspects, however they can be larger and less versatile pertaining to storage. On the various other hand, versatile containers, like bulk bags, are very easy and light-weight to deal with; however, they may not give the exact same degree of protection for sensitive materials. Furthermore, some containers are created for particular items, which can boost performance yet restriction adaptability. Eventually, the option of bulk container relies on stabilizing these advantages and downsides to meet the certain storage and transportation requirements of the materials included.

Key Considerations for Selecting Bulk Containers

Choosing the right mass container needs cautious factor to consider of numerous important variables, as the selection can substantially affect both effectiveness and security during storage space and transport. The product of the container ought to straighten with the nature of the items, ensuring compatibility to prevent contamination or degradation. Next off, the container's size and ability should match the quantity of items being kept or delivered, enhancing area usage. Furthermore, the weight of the container is important for both handling and transportation expenses. Resilience and resistance to ecological elements are vital for preserving item integrity. Lastly, conformity with sector policies and requirements need to be verified to prevent legal repercussions (Plastic Bulk Containers). By evaluating these factors, companies can make educated decisions that boost operational effectiveness

Industry-Specific Mass Container Requirements

Various sectors enforce specific needs for mass containers based on the nature of the products took care of and the regulative landscape they run within. As an example, the food and beverage sector mandates containers that are compliant with health policies, assuring they are quickly cleanable and non-toxic to stop contamination. On Reusable Bulk Plastic Containers the other hand, the chemical industry frequently needs containers that can hold up against harsh materials, requiring products like high-density polyethylene or steel. In drugs, mass containers have to stick to strict standards to secure product integrity and guarantee traceability. Additionally, industries such as agriculture may focus on containers that promote oygenation or wetness control, while the building and construction sector may prioritize durability and load-bearing ability. Each demand shows the one-of-a-kind challenges and compliance needs of the respective industry.

Finest Practices for Maintaining Product Honesty Throughout Storage Space and Transfer

Keeping item stability throughout storage space and transportation is essential, as also small messing up can bring about significant losses or top quality destruction. To guarantee perfect problems, temperature level and humidity levels need to be closely kept an eye on, particularly for delicate products. Utilizing ideal mass containers developed for details products is crucial, as these containers provide necessary protection against contamination and physical damage. Normal examinations of containers and storage centers can help determine prospective problems prior to they escalate - Bulk Plastic Containers. Additionally, appropriate labeling and documents streamline the managing process, decreasing the threat of errors. Training employees in finest techniques for taking care of and carrying products further safeguards honesty, making sure that items show up at their location in the intended condition. Executing these finest methods can substantially improve total efficiency and reliability

Frequently Asked Concerns

What Are the Prices Connected With Bulk Container Rental Versus Acquisition?

How Can I Tailor Mass Containers for Certain Products?

To customize mass containers for particular products, one can customize attributes, materials, and dimensions such as ventilation or insulation. Branding alternatives, shade coding, and classifying additionally boost functionality and identification for reliable storage space and transport.

Are There Eco-Friendly Mass Container Options Available?

What Is the Ordinary Lifespan of Various Mass Containers?

The ordinary lifespan of bulk containers varies widely; plastic containers last 5-10 years, metal alternatives can last 10-20 years, while wooden containers generally have a life expectancy of 3-7 years, depending on usage and upkeep.

Just how Do I Ensure Conformity With Rules for Bulk Container Use?

To ensure conformity with laws for bulk container use, one need to consistently review and comprehend suitable regulations, maintain correct documents, conduct safety audits, and implement training programs for workers dealing with these containers. Reusable Bulk Plastic Containers.

Bulk containers offer as necessary devices in the storage and transport of different products, varying from liquids to solids. Each type of bulk container serves an unique function, helping with effective activity and storage space, while making sure safety and conformity with market criteria. Different markets enforce certain requirements for mass containers based on the nature of the materials managed and the regulative landscape they operate within. Making use of ideal mass containers designed for details items is vital, as these containers offer required security versus contamination and physical damages. To personalize bulk containers for particular items, one can customize functions, products, and dimensions such as ventilation or insulation.